In older devices, for example measurement technology, one often finds cable harnesses tied by hand. This refers to a number of wires that are knotted together with so-called binder twine to form a stable structure. This type of wiring has to be done manually and is therefore very time-consuming. For this reason, it is essentially only used in the aerospace industry today. There are various other ways of producing wire harnesses, such as with cable ties or hoses, etc. But this article is only about the original method with twine. I can imagine that the first wire harnesses were made for telephone exchanges. In any case, the builders of analog switching technology were true masters at crunching wires together.

Basically, cable harnesses have several advantages.

- The cables are more stable when tied together.

- Less space is needed for the cabling.

- Errors during assembly or maintenance are avoided.

- Overall, the result is very good fail-safety.

Recently, I restored an old oscilloscope and had to add the missing harnesses again. That was the reason why I dealt with this topic in more detail. Here in the picture you can see the first result and I am overall satisfied with it.

First condition to tie a harness yourself is the right twine. In the past this was a waxed thin natural yarn, probably jute, sisal or flax. In very old telephone switching equipment from the late 20’s or 30’s, which I cannibalized as a kid, you can still find such yarn. Nowadays the material is something like dental floss with a lot of wax. There are only a few suppliers left who supply end users with it. SEGOR-electronics GmbH from Berlin carries it in its assortment under the name “Abbindegarn“. As “Abbindeschur” I bought my supply at Bürklin Elektronik. I also strongly recommend to use a binding twine explicitly made for wire harnesses. Other materials do not work as well and may not be stable over time.

I came across an alternative variant that I still like: durable yarn, probably star twine is dipped in hot beeswax.

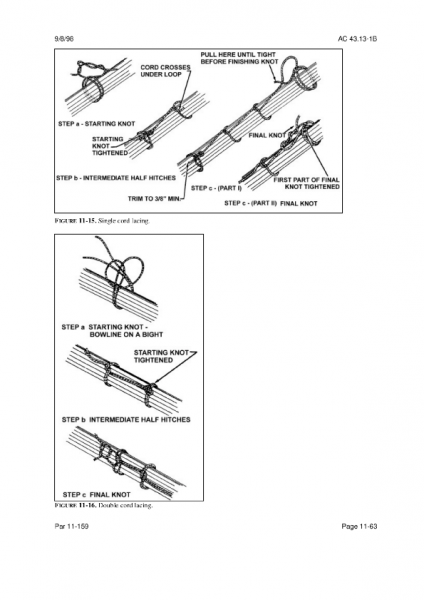

Now the art of knotting is still missing. For an easy start I recommend to follow the guidelines of the FAA, the “United States Federal Aviation Administration”. This has published in its “Advisory Circular” 43.13-1B, Chapter 11 “Aircraft Electrical Systems” instructions that contain only two variants of tying and are so simple and clear.

Quelle: FAA AC 43.13-1B, Chapter 11

Another tip: You can build up the wiring harness in at least two dimensions on a board with small nails. To do this, hammer in a small nail at each bend and at each branch. The wires can then be bent along there, then tied. If the shape of the tree goes into the third dimension, it becomes more difficult and I would wire and bind it directly in the device.

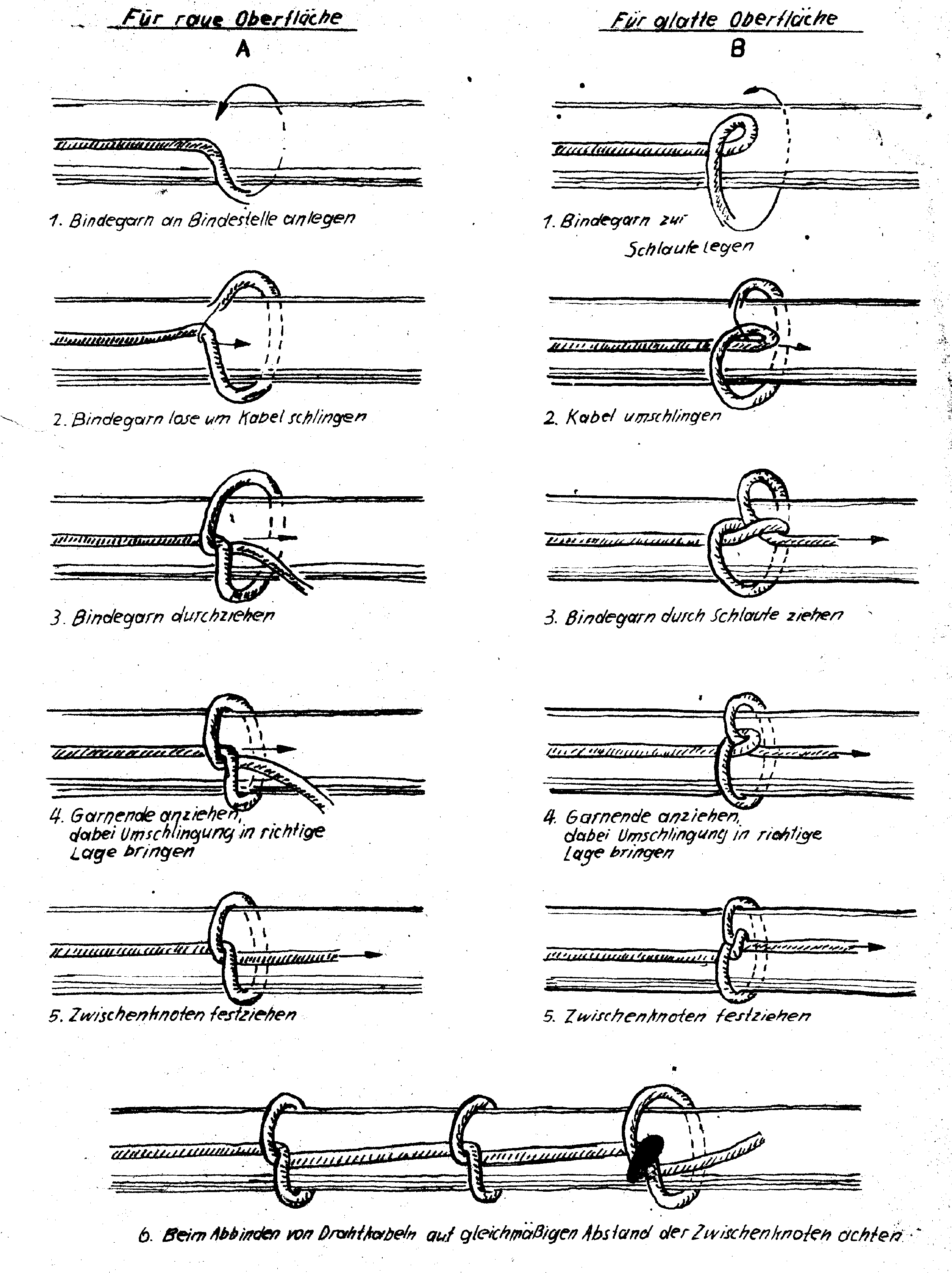

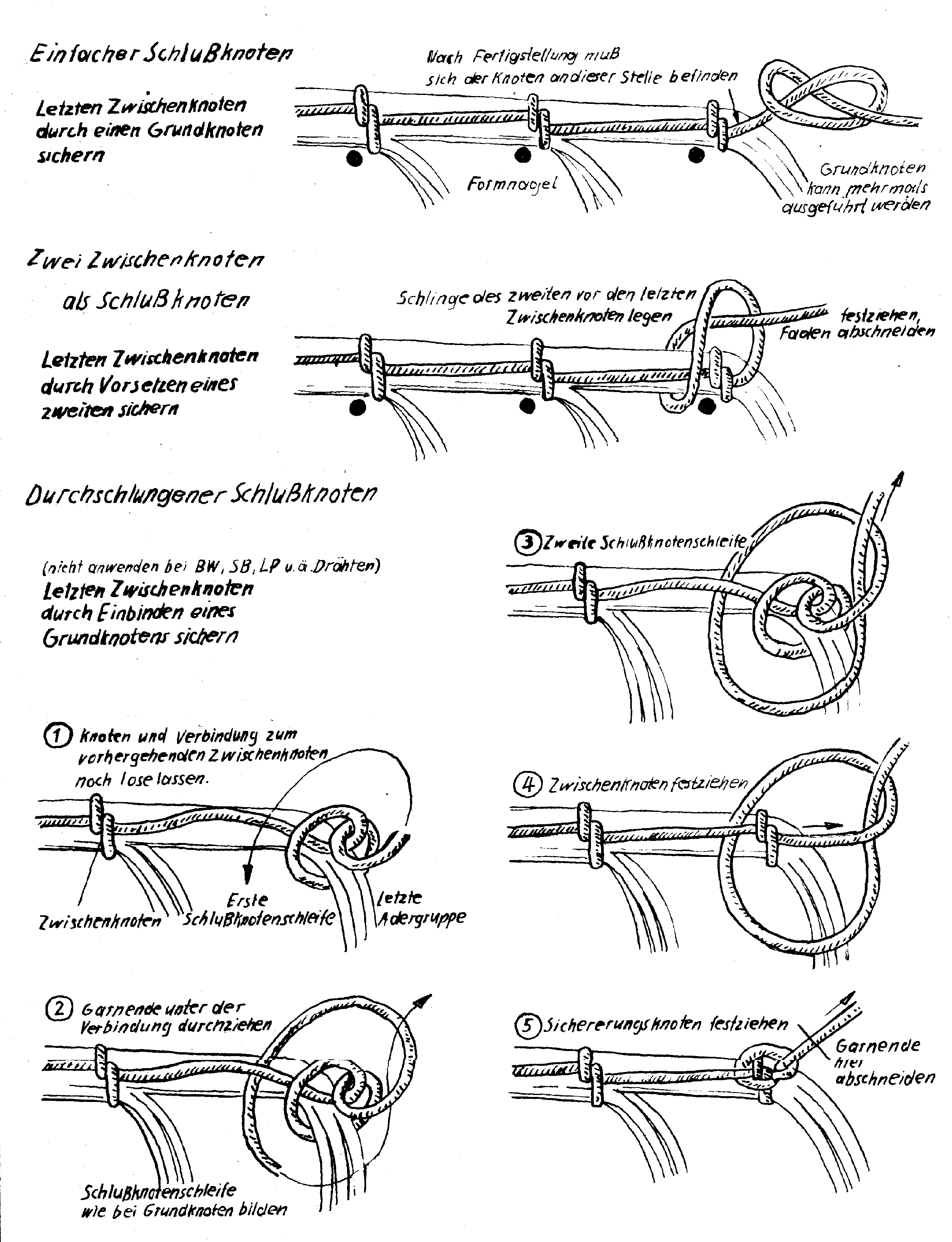

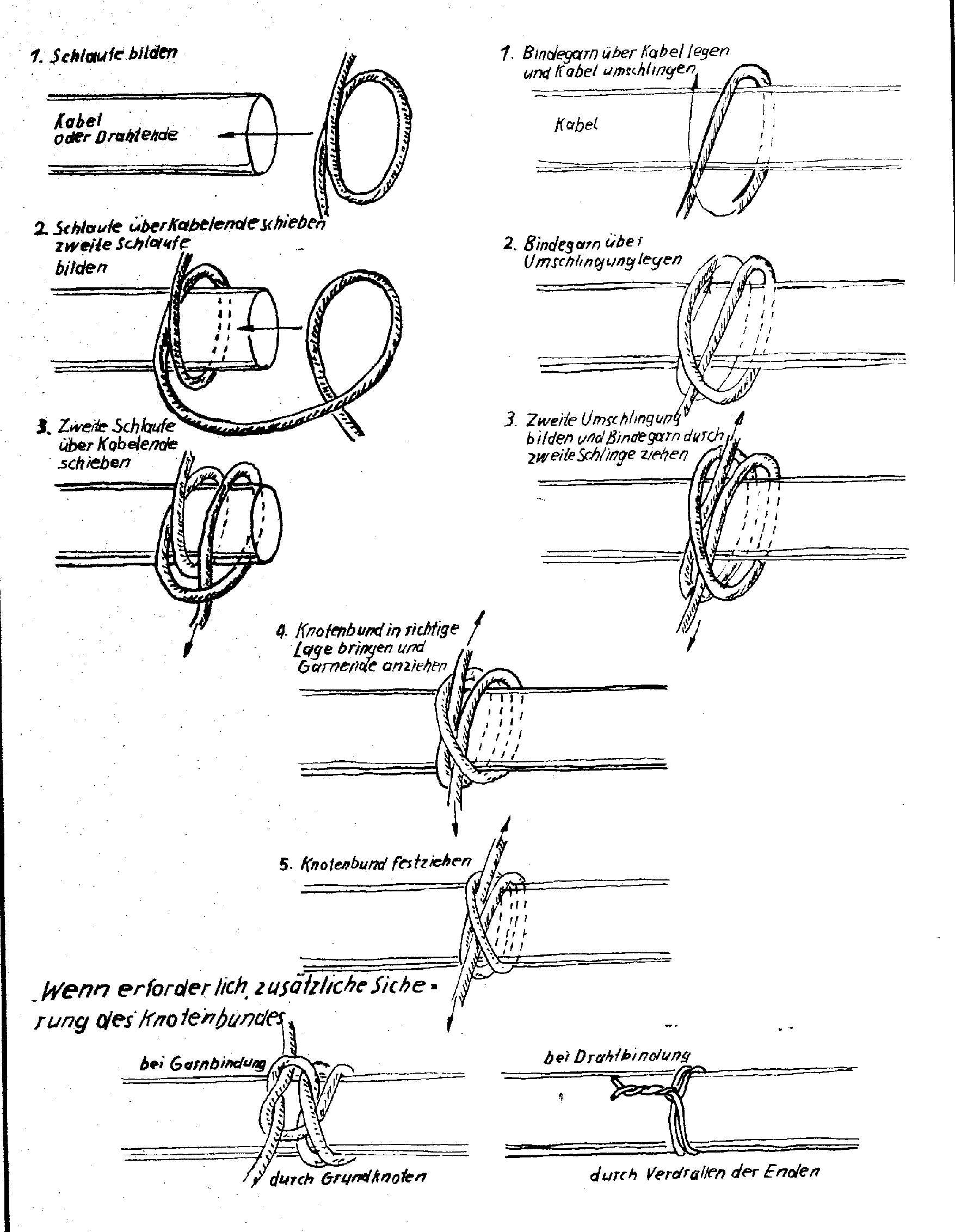

At mikrocontroller.net you can find a thread which also deals with this topic. From this thread come the following multiple variants for node binding. In the end you have to decide for one variant. I decided like this:

- Initial knot: “Form A mit Sicherheitsknoten”

- Intermediate knot: “Form B für glatte Oberflächen”

- Final knot: “Durchschlungener Schlussknoten”

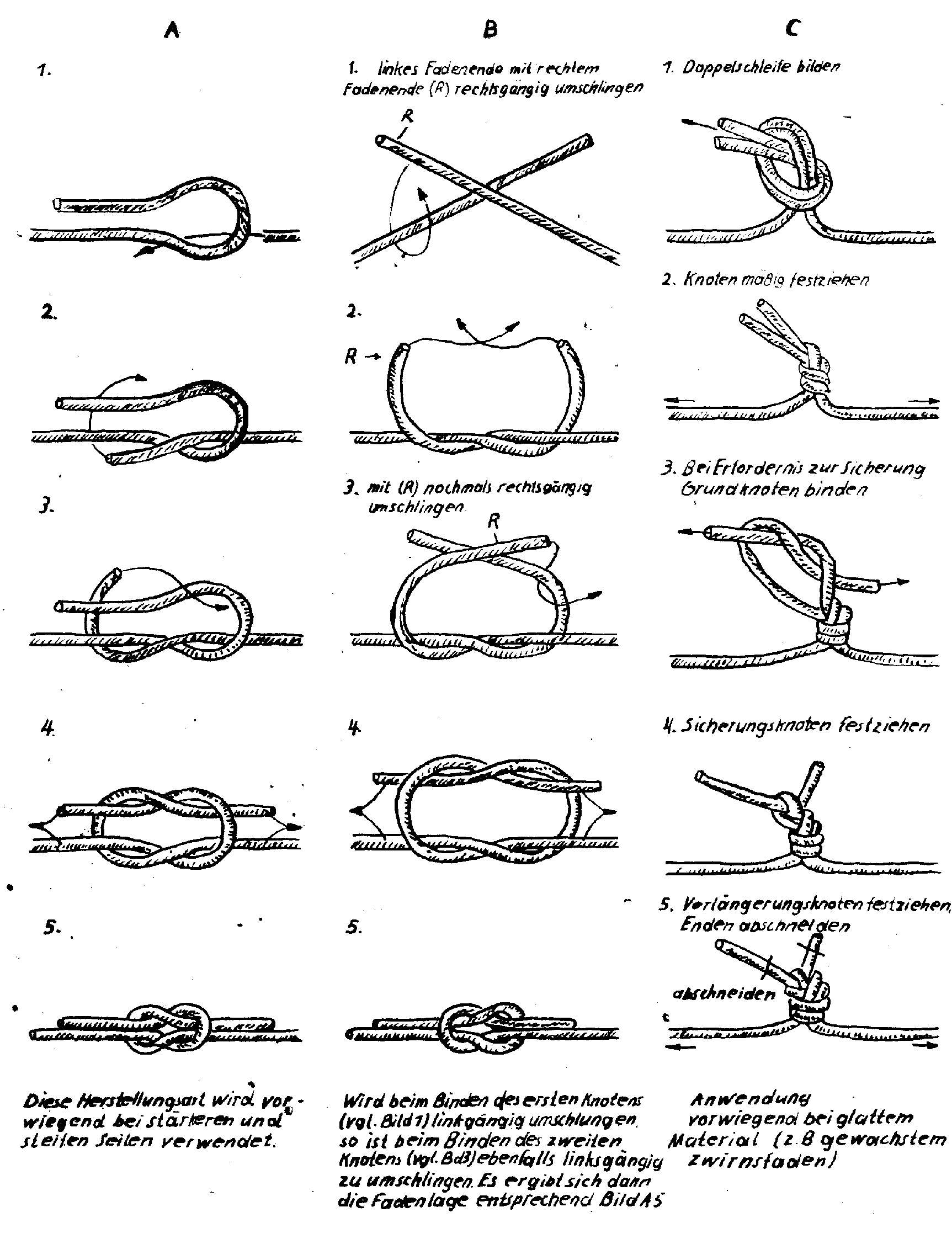

Grundknoten, Quelle: www.mikrocontroller.net /attachment/49981/Blatt412_Grundknoten.png

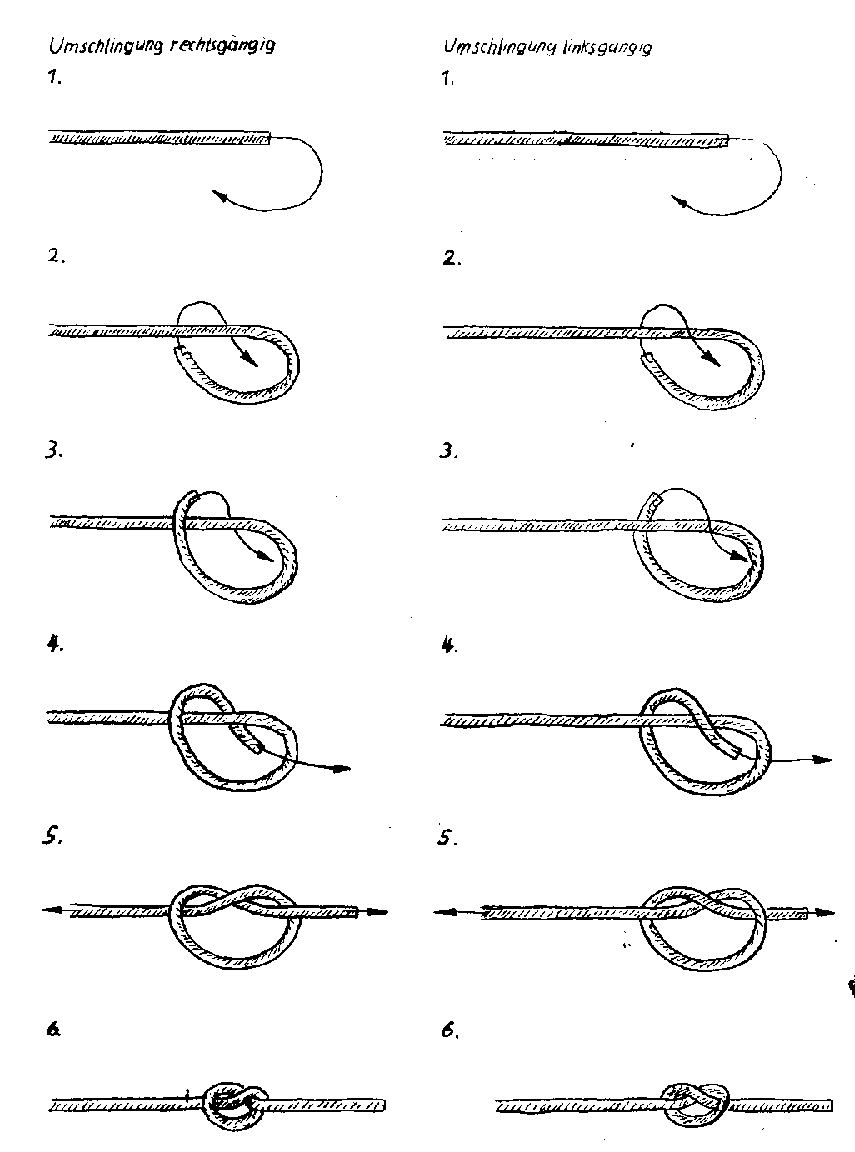

Verlängerungsknoten, Quelle: www.mikrocontroller.net /attachment/49982/Blatt413_Verlaengerungsknoten.png

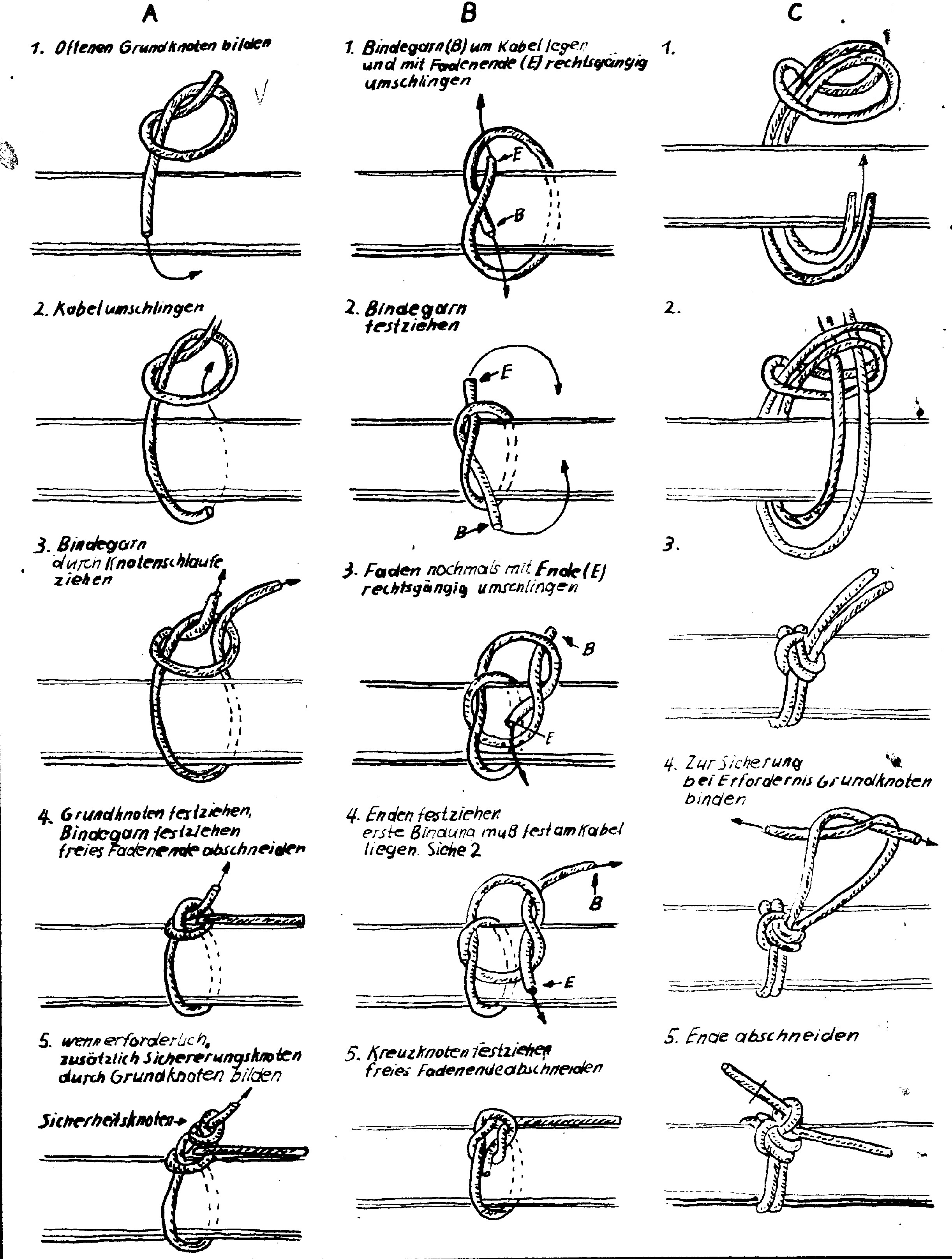

Anfangsknoten, Quelle: www.mikrocontroller.net /attachment/49983/Blatt414_Anfangsknoten.png

Zwischenknoten, Quelle: www.mikrocontroller.net /attachment/49984/Blatt415_Zwischenknoten.png

Schlussknoten, Quelle: www.mikrocontroller.net /attachment/49985/Blatt416_Schlussknoten.png

Knotenbund, Quelle: www.mikrocontroller.net /attachment/49986/Blatt418_Knotenbund.png

The full thread is here: https://www.mikrocontroller.net/topic/64283

Quelle:

Quelle:  Grundknoten, Quelle: www.mikrocontroller.net

/attachment/49981/Blatt412_Grundknoten.png

Grundknoten, Quelle: www.mikrocontroller.net

/attachment/49981/Blatt412_Grundknoten.png Verlängerungsknoten, Quelle: www.mikrocontroller.net

/attachment/49982/Blatt413_Verlaengerungsknoten.png

Verlängerungsknoten, Quelle: www.mikrocontroller.net

/attachment/49982/Blatt413_Verlaengerungsknoten.png Anfangsknoten, Quelle: www.mikrocontroller.net

/attachment/49983/Blatt414_Anfangsknoten.png

Anfangsknoten, Quelle: www.mikrocontroller.net

/attachment/49983/Blatt414_Anfangsknoten.png Zwischenknoten, Quelle: www.mikrocontroller.net

/attachment/49984/Blatt415_Zwischenknoten.png

Zwischenknoten, Quelle: www.mikrocontroller.net

/attachment/49984/Blatt415_Zwischenknoten.png Schlussknoten, Quelle: www.mikrocontroller.net

/attachment/49985/Blatt416_Schlussknoten.png

Schlussknoten, Quelle: www.mikrocontroller.net

/attachment/49985/Blatt416_Schlussknoten.png Knotenbund, Quelle: www.mikrocontroller.net

/attachment/49986/Blatt418_Knotenbund.png

Knotenbund, Quelle: www.mikrocontroller.net

/attachment/49986/Blatt418_Knotenbund.png

Hallo Uwe,

eine weitere Bezugsquelle für Endverbraucher findest Du neben Bürkle in der Fa. Segor Elektronik in Berlin:

http://www.segor.de

Ggf. einfach Abbindeschnur in das Suchfeld eingeben und bestätigen.

Viele Grüße

Harry

Hallo Harry,

vielen Dank für den Tipp. Ich habe den link zu Segor in den Artikel aufgenommen. Bin alter Stammkunde dort, da ich in der Nähe wohne. Anscheinend hatte ich das im Katalog damals nicht gefunden unter dem Namen.

Viele Grüße,

Uwe

Interessant, dass man einen Kabelbaum selbst binden kann. Ich bin Einsteiger. Danke der den Blog zur Technik.